DUCHESSE fabric for Brenners Park-Hotel

For 150 years the original building of the Oetker Collection in Baden-Baden represents impressive grand hotels and passionate commitment for the guests. On this great occasion the anniversary commemorative publication was written:

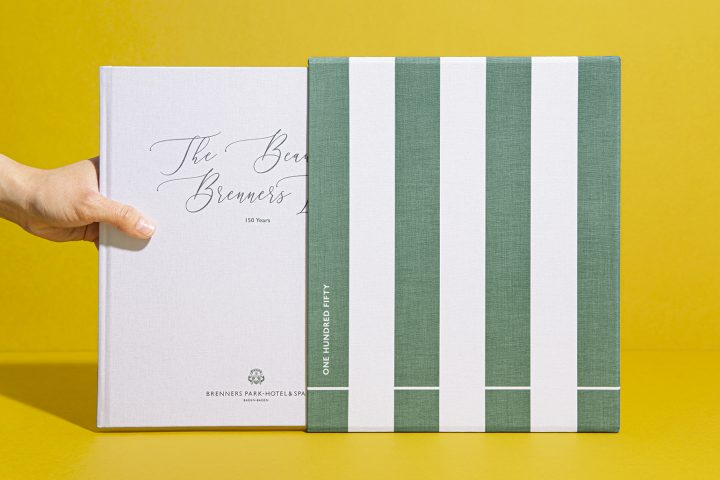

„Das schöne Brenners Leben – 150 Jahre“

Portraits and personal inputs of contemporary witnesses, interesting things found in the archive of the house, embedded in regional and contemporary history: when there becomes a story of facts, memories come alive!

The content of the very beautiful anniversary work was printed in offset printing on 170 g/m² Condat matt Périgord 4/4-coloured plus partial printing varnish on the KBA Rapida 165 5+L SiS.

The design of cover and slipcase reminds visually and haptically of the green-white sunblinds of the house.

As cover material for the book and the slipcase our DUCHESSE 90100 diamantweiß was selected on the spur of the moment, because of its unique grippy haptic. This was printed for the cover of the book with the non-standard Pantone colours green 625 (modified) and grey 445c in offset printing. The cover of the slipcase was printed 1/0-coloured, with Pantone green 625 (modified) as well. For both covers a Ryobi printing machine was used.

Offset printing of fabrics is generally possible, the different structures of the fabrics allow this. Also in this case the principle is that the colour reproduction on different printing fabrics will turn out differently.

By the right choice of the hardness of the rubber blanket, the back pressure and the printing pressure the extensive block stripes as well as the fine lines of the logo were reproduced very well in spite of the raw surface structure of the DUCHESSE.

The magnificient masterpiece is therefore a beautiful example how well fabrics can be printed by offset printing.

The configuration of the press and the components used (printing plates, inks, etc.) always depend on the specific configuration in the printing plant. And of course on the printing image and printing subject as well. Therefore, we can only recommend rough points of reference how printing on fabrics can work:

- Design elements with 100% area coverage are most recommended. However, make sure that with 4-colour printing the build-up of a full area of process colours is kept to a minimum.

- The use of a 60 AM screen is enough. Use purely oxidative drying inks (foil inks) and a very soft rubber blanket.

- When starting printing, use very little damping water and add it slowly until the print result is good.

- The pressure between plate and rubber blanket has to be (very) high.

- Normal printing powder is used, typical addition.

- Print at the maximum format 50 x 70 cm, it is even better to print in one-up production.

Offset printing on fabrics needs a lot of experience. We recommend printing tests in advance to evaluate the printing result and to check if it is possible. Impressive offset printing results have already been achieved on our very different fabrics!

You can also be inspired by our print sample folder. An accomplished product which shows you the possibilities for printing on the PEYER materials.